2 min read

Tracing is a crucial step in the soap-making process, particularly when using the cold process method. It is the point at which the soap mixture reaches a certain consistency, indicating that it's ready to be poured for solidification. Complete saponification is not possible without tracing.

What is Tracing?

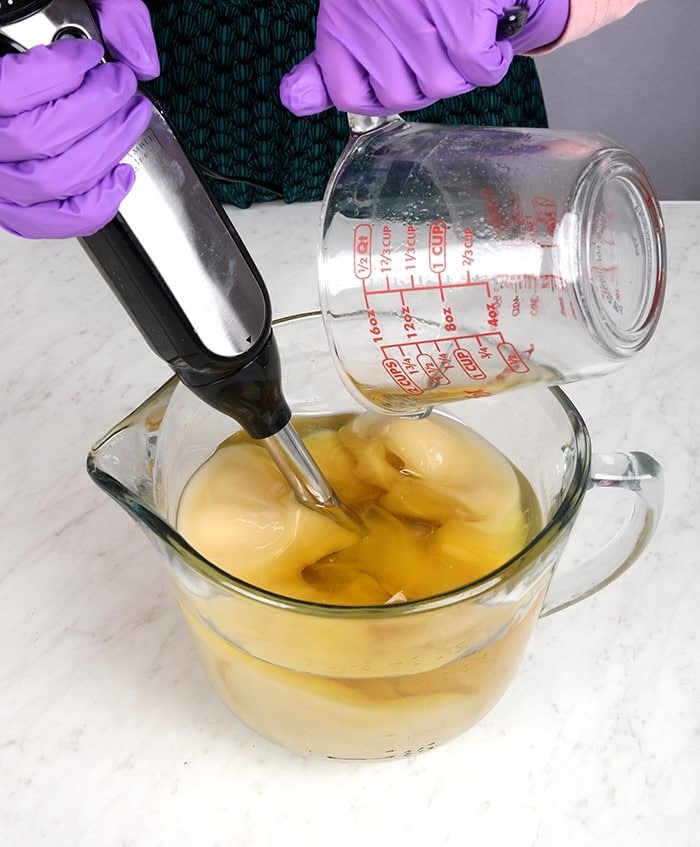

Tracing refers to the moment when the soap batter becomes thick enough to hold a trace. This means that when you drizzle a small amount of the batter onto the surface, it leaves a visible trace or trail. It's a visual cue that the saponification process, where oils and lye combine to form soap, is progressing steadily.

Tracing is a crucial step in the soap-making process, particularly when using the cold process method. It is the point at which the soap mixture reaches a certain consistency, indicating that it's ready to be poured for solidification.

- Texture: Tracing ensures that the soap batter has the right consistency for pouring. If it's too thin, it might not set properly, leading to a soft or crumbly bar. If it's too thick, it can be difficult to pour and might trap air bubbles.

- Scent: Tracing is the ideal time to add essential oils or fragrance oils to your soap. If added too early, they can interfere with the saponification process.

- Color: If you're using colorants, adding them at the tracing stage helps prevent them from sinking to the bottom of the soap.

Tracing Tips For Beginners

- Visual Inspection: Scoop a small amount of the batter and let it drip slowly from a spoon. If it leaves a clear trail, it's likely traced.

- The Ripple Test: Gently swirl the batter in your pot. If it leaves ripples that remain visible for a few seconds, it's a good sign of tracing.

- The Ribbon Test: Lift a small amount of the batter and let it drip back into the pot. If it forms a ribbon that takes a few seconds to disappear, your soap is likely traced.

Tips for Tracing the First Time

Remember, tracing can vary depending on factors like temperature, humidity, and the specific ingredients you're using. It's a skill that comes with practice. By mastering the art of tracing, you'll be well on your way to creating beautiful, high-quality handmade soap.